The Importance Of FRP Motor Fan Covers, Fiberglass Air Inlet Hoods And Exhaust Vent Covers

Product production process is the earliest and most common molding process in resin composite production. The process of hand paste molding is based on resin mixture with curing agent as matrix, glass fiber and its fabric as reinforcing material, and the two are bonded together by manual laying and coating on the mold to cure the molding by chemical reaction. Finally, the composite products were obtained by demoulding.It is a very important part of the poultry house environmental control system to prevent rain and water accumulation, solve the water inlet problem, wind and dust prevention and insulation, double protection to prevent winter heat dissipation, and use with Air inlet and Exhaust fan.

Product features

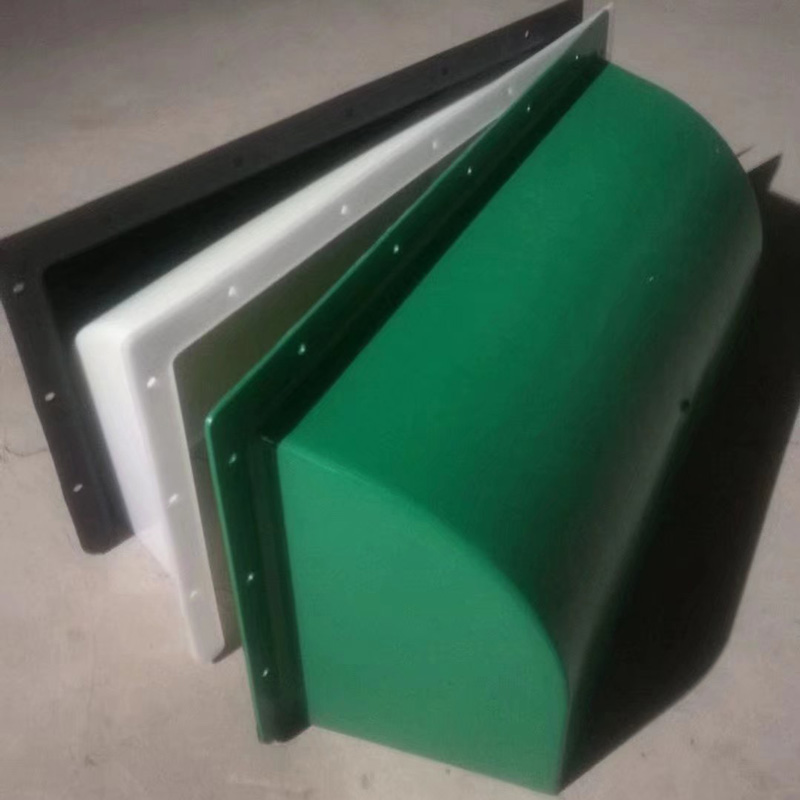

- Protects your fans and shutters and vent against snow, rain and wind;

- Includes assembly hardware and instructions.

- according to the design requirements of the product, in different parts of arbitrary reinforcement, flexibility;

- Curing at room temperature and forming under atmospheric pressure;

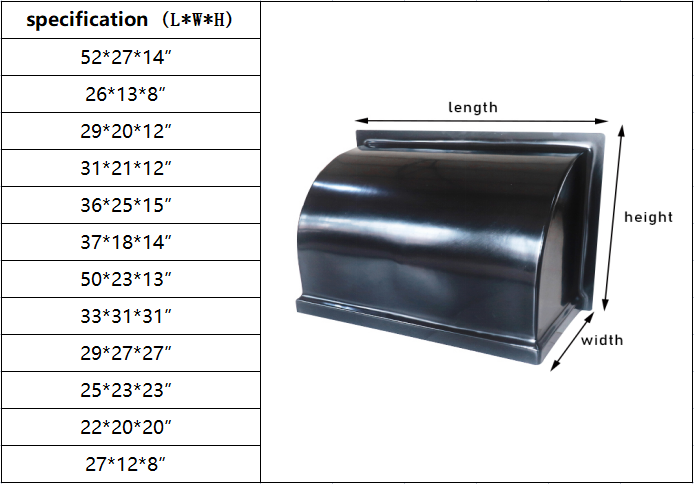

- Products style can be customized;

- Product color can be customized;

Please feel cost-free to send us your specifications and we'll respond to you asap. We've got a professional engineering team to serve for the every single detailed needs. So that you can meet your desires, please really feel cost-free to contact us. You could send us emails and call us straight. Additionally, we welcome visits to our factory from all over the world for much better recognizing of our corporation. In our trade with merchants of several countries, we often adhere to the principle of equality and mutual advantage. It is our hope to market, by joint efforts, both trade and friendship to our mutual benefit. We look forward to getting your inquiries.

Introduce:

In a variety of industrial environments, ensuring the safety and efficiency of machinery and equipment is critical. Among the many key components, three cannot be ignored: FRP motor fan cover, fiberglass air intake cover and exhaust mask. These components play an important role in improving machine performance and service life while ensuring worker and environmental safety. This blog will delve into the importance of these three components and how they contribute to overall industrial efficiency.

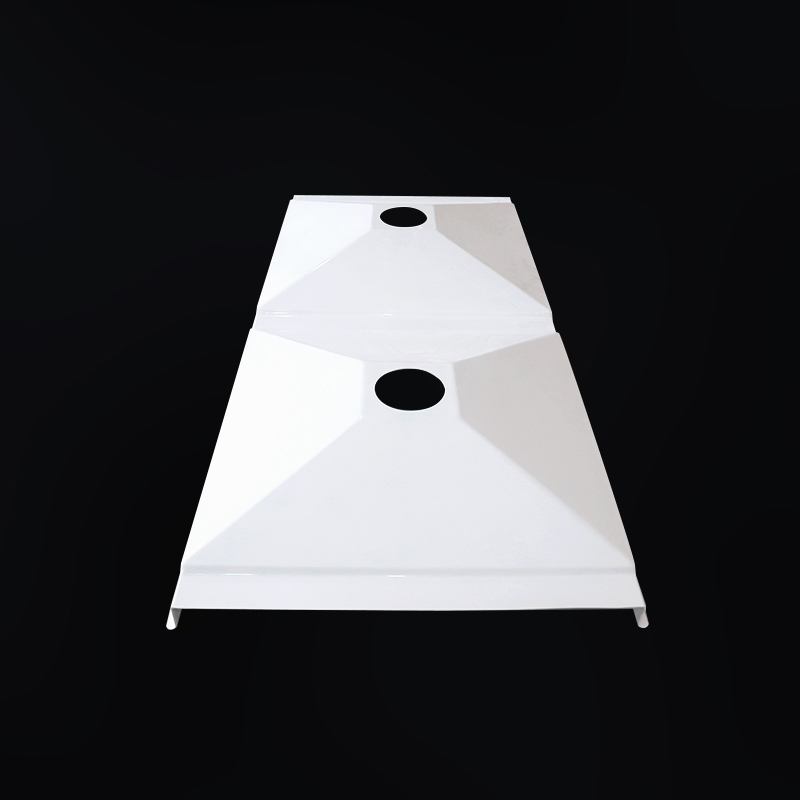

Enhance safety with FRP motor fan shrouds:

FRP motor fan shrouds are typically made from strong, fire-resistant materials such as fiberglass-reinforced plastic (FRP) and prevent workers from direct contact with the rotating motor fan blades. These covers act as a barrier, reducing the risk of accidental injury, such as cuts or amputation. Additionally, FRP’s durable and non-conductive properties minimize the risk of electric shock, providing workers with an extra layer of safety.

In addition, the fiberglass motor fan guard prevents foreign objects from entering the motor housing, thereby protecting the internal components from damage. Regular maintenance and inspection of these covers ensures that they do not have cracks or damage that could affect their effectiveness.

Use fiberglass air intake hoods to ensure clean air:

Fiberglass air inlet hoods help maintain air quality within industrial facilities. These vent hoods are designed to prevent contaminants such as dust, dirt, debris or insects from entering the ventilation system. By filtering out these unwanted elements, fiberglass air intake hoods help maintain a clean work environment and prevent potential damage to sensitive mechanical parts such as filters, coils or heat exchangers.

Additionally, fiberglass air intake hoods are corrosion-resistant and can withstand harsh weather conditions. This durability ensures a longer service life, reducing the need for frequent replacement and saving on maintenance costs.

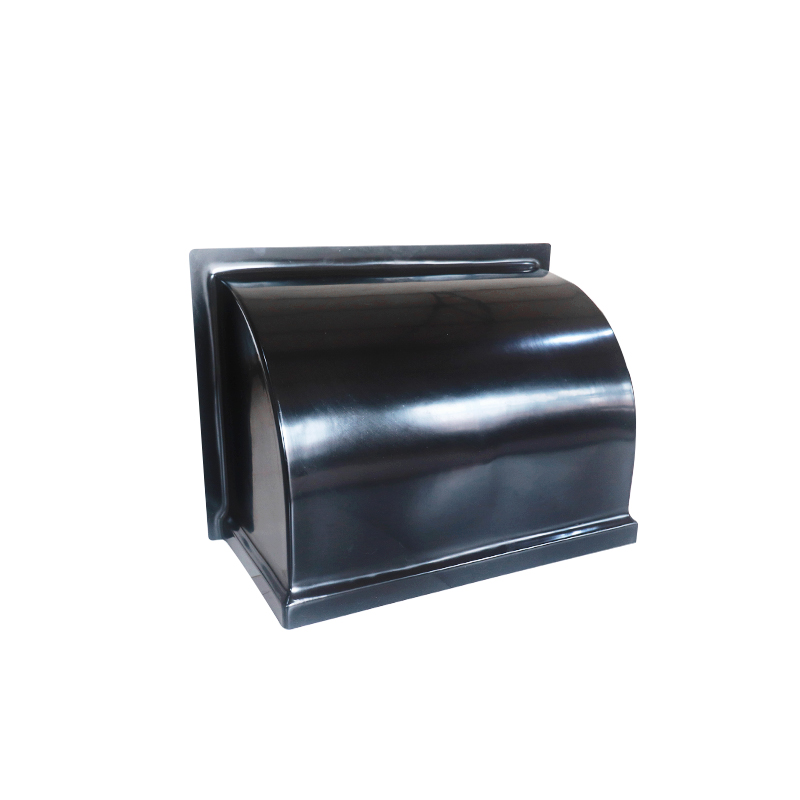

Optimize system performance with vent covers:

Exhaust vent covers are vital to maintaining optimal system performance by keeping unwanted elements out of your exhaust system. These covers prevent the entry of rainwater, pests or debris, which can impede the flow of exhaust gases and seriously reduce the efficiency of the machinery. By ensuring unimpeded flow, vent covers contribute to consistent equipment operation, preventing potential failures and reducing downtime.

In addition, exhaust vent covers are made of durable materials such as fiberglass or stainless steel for superior corrosion resistance. This corrosion resistance is particularly beneficial in industrial environments where machinery is exposed to a variety of chemicals or extreme environmental conditions.

In conclusion:

In summary, FRP motor fan covers, FRP air inlet covers, and exhaust masks play a vital role in ensuring the safety and efficiency of machinery in industrial environments. These components act as a physical barrier to the rotating fan blades while protecting the internal mechanical components from damage, thus protecting workers from potential injury. Additionally, by keeping contaminants out, these covers help maintain clean air and optimize overall system performance. Therefore, investing in high-quality fiberglass motor fan covers, fiberglass air intake hoods, and exhaust masks is critical for any industrial facility that aims to prioritize worker well-being and seamless operation of machinery.

product packing

Exhibition