Significant Advantages Of Fiberglass I-Beams In Construction

Introduce:

In the field of construction, innovation plays a vital role in creating structures that are strong yet cost-effective and sustainable. One innovation that has gained popularity in recent years is the fiberglass I-beams. These structural components offer a wide range of advantages over traditional materials, making them the first choice for a variety of construction projects. In this blog, we’ll explore the significant benefits of fiberglass I-beams and reveal their potential to revolutionize the construction industry.

Advantages of fiberglass I-beam:

1. Superior strength to weight ratio:

Fiberglass I-beams are known for their excellent strength-to-weight ratio. They offer similar structural integrity while being significantly lighter than their steel counterparts. This feature not only simplifies transportation and installation, but also reduces the overall construction load, allowing for greater design flexibility.

2. Corrosion resistance:

One of the biggest challenges with traditional steel beams is corrosion. Over time, exposure to moisture, chemicals, and changing weather conditions can cause steel beams to deteriorate, compromising the structural integrity of a building. Fiberglass I-beams, on the other hand, are highly resistant to corrosion. They won't rust or be affected by harsh environments, making them ideal for coastal areas or areas prone to chemical exposure.

3. Electrical insulation and thermal insulation:

Fiberglass I-beams have excellent electrical and thermal insulation properties. Unlike metal structures, which conduct electricity and can pose a potential hazard, fiberglass beams do not conduct electricity. This feature is particularly useful in environments where electrical safety is a concern, such as power plants or chemical processing facilities. In addition, fiberglass I-beams act as effective insulators, reducing heat transfer, thereby increasing the building's energy efficiency.

4.Design flexibility:

The flexibility of fiberglass I-beams allows architects and engineers to create complex and innovative designs. These beams can be easily molded into a variety of shapes and sizes, allowing the freedom to create a structure that best suits the project requirements. The inherent adaptability of fiberglass also allows for easy modifications during construction, saving cost and time.

5. Long service life and low maintenance cost:

Fiberglass I-beams have an impressive service life due to their inherent durability and resistance to degradation. They do not require regular maintenance, repainting or galvanizing like steel beams. Additionally, the lack of corrosion eliminates the need for costly repairs and replacements over time, resulting in significant cost savings for the construction industry.

In conclusion:

The introduction of fiberglass I-beams marked a major leap forward in the practice of enhanced construction. Their strength, corrosion resistance, electrical and thermal insulation, design flexibility and low maintenance costs make them an excellent alternative to traditional steel beams. As the construction industry continues to prioritize sustainability and cost-effectiveness, fiberglass I-beams certainly offer a promising solution.

Using fiberglass I-beams not only increases the durability and longevity of your structure, but also helps create a greener, safer future. As manufacturing technology continues to advance and awareness of its advantages increases, it’s no surprise that fiberglass I-beams are rapidly gaining popularity in the construction industry. Ultimately, these innovative beams have the potential to reshape the way we build, making the process more efficient, economical and environmentally friendly.

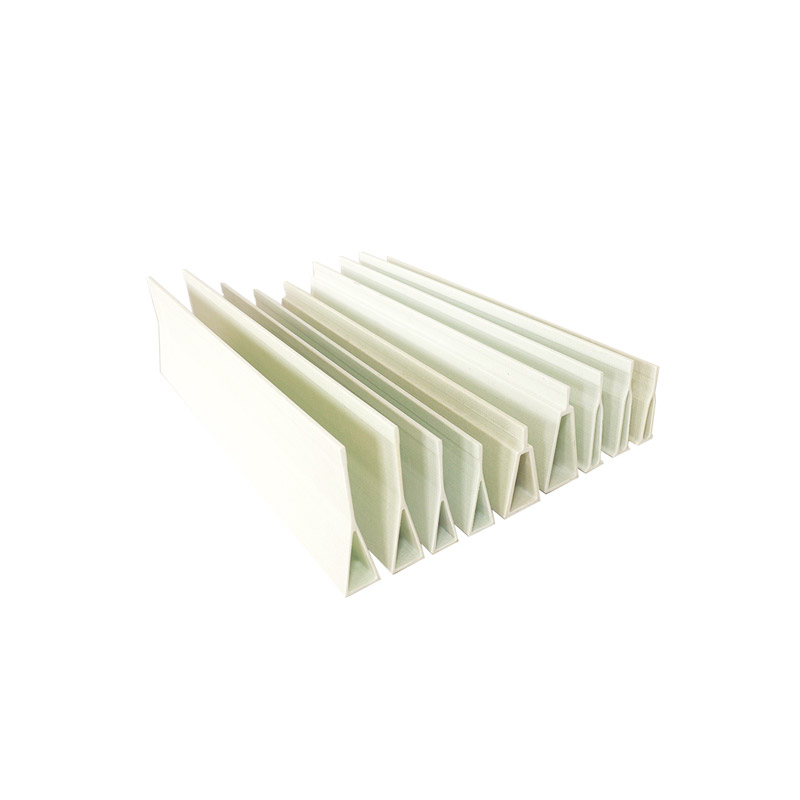

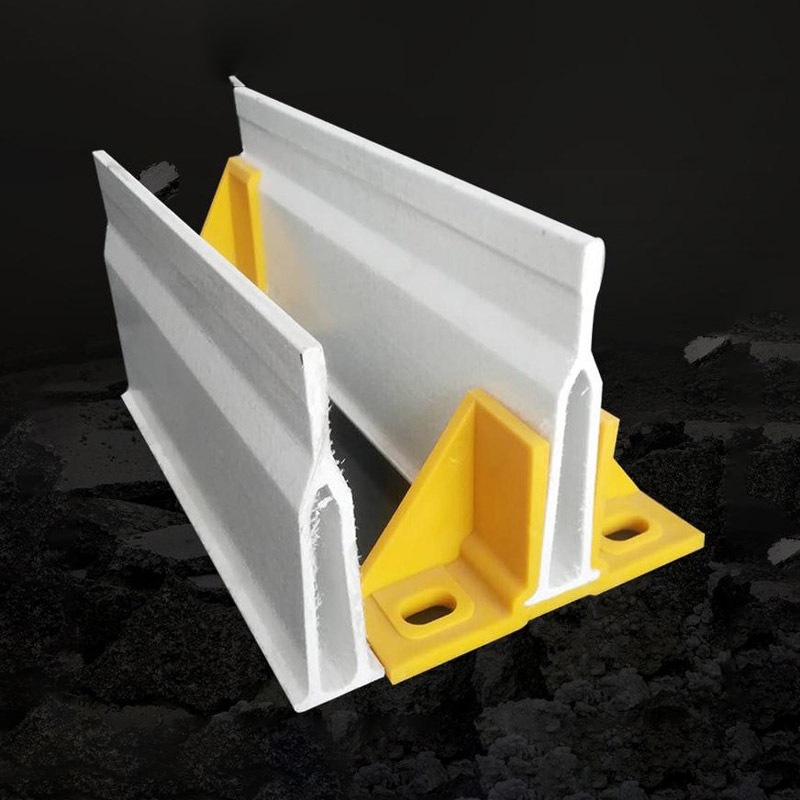

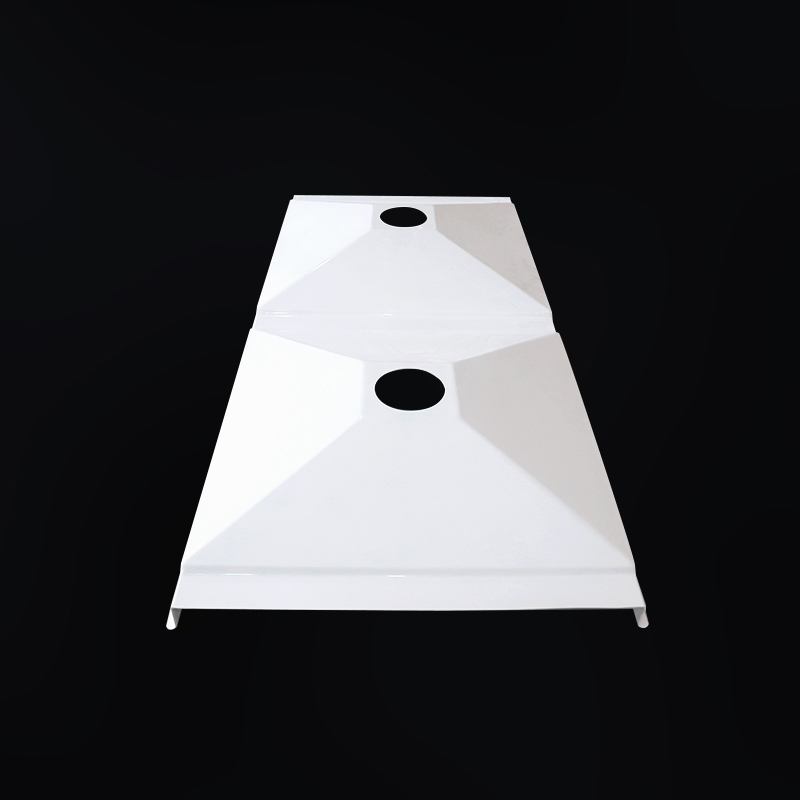

Product features

corrosion resistance, acid and alkali resistance, anti-aging, no bacteria, strong bearing capacity.

Glass steel beam for breeding is made of unsaturated resin by pultrusion molding, has the good characteristics of glass steel products, more durable than cast iron beam, beautiful and generous.

The FRP beams with high quality exports to the Netherlands, the United States, South Africa and other countries.

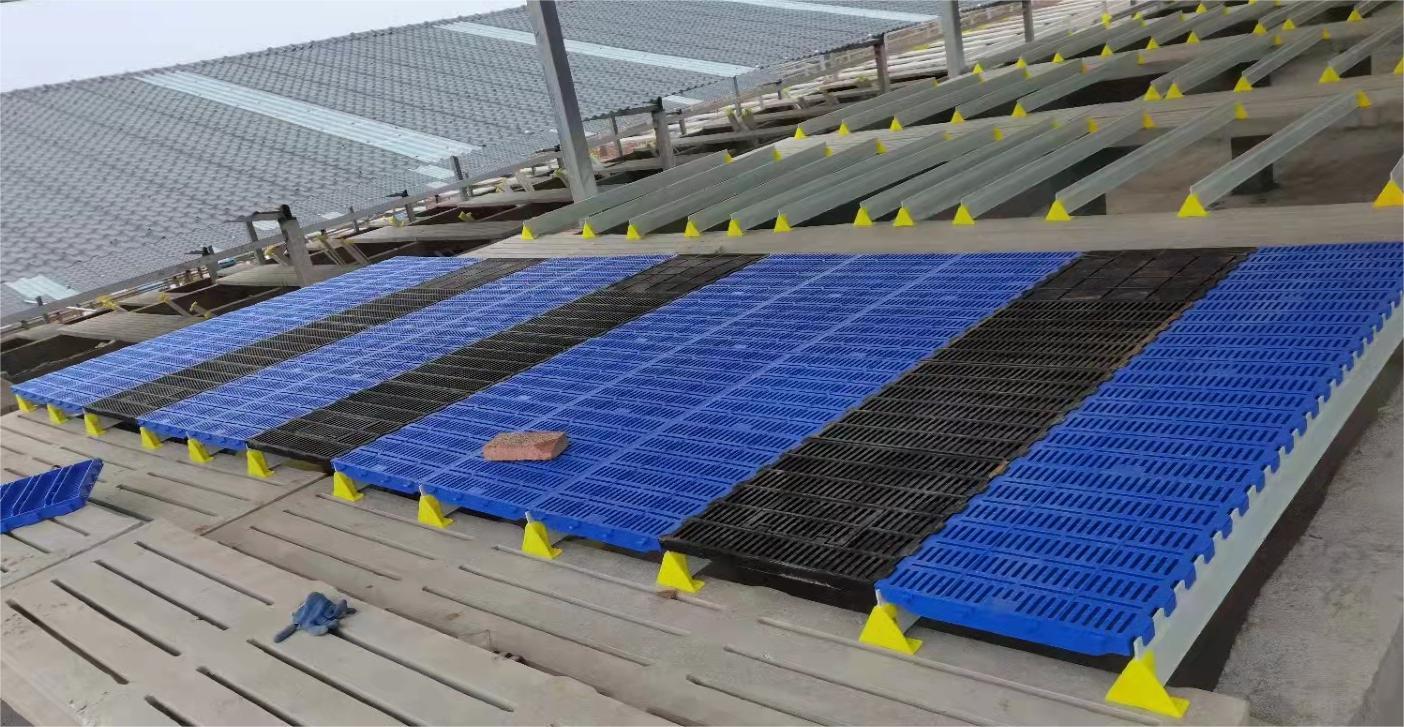

Now The FRP beams is popular for pig farm, goat farm and poultry flooring support system .It is ideal alternative profile for those traditional material. The FRP Beams are developed and widely used in poultry farms. At present .The most widely used one is sow beds , with a span of 2.4 meters . They also can be used in pig farms for the maintenance of piglets. They can span 3.6meters without any support in the middle and have been guaranteed for more than 20 years.

In recent years, more and more sheep shed construction is also using FRP support beams And achieved a very good effect.

Advantages of FRP floor support beam for nursery bed in piggery

1. piggery nursery bed FRP floor support beam light weight: its specific gravity is about 1.8, its weight is only 1/4 of steel, is 2/3 of aluminum;

2. piggery nursery bed FRP floor support beam strength is high: its strength is ten times of hard PVC, strength greatly exceeds aluminum, 1.7 times of ordinary steel;

3. piggery nursery bed FRP floor support beam corrosion resistance: it is not rust, mold, rot, do not need to paint, can withstand many gas, liquid medium corrosion;

We firmly think that we have the full capability to give you contented merchandise.Wish to collect concerns within you and build a new long-term cooperative relationship. We all significantly promise: the same excellent, better selling price; exact selling price, better quality.

product packing

Exhibition