Introduce:

As the demand for efficient motor performance continues to grow, industries continue to seek innovative solutions to increase motor functionality and service life. One of the focus areas is the use of FRP (fiber reinforced plastic) motor covers and fiberglass air intake hoods. These components play a vital role in improving the overall efficiency and performance of the motor. In this blog post, we will explore the benefits of using FRP motor covers and fiberglass air intake hoods, their functions, and how they can help optimize motor performance.

1. Fiberglass motor cover:

FRP motor covers are designed to provide protection for the motor unit while effectively controlling noise levels and keeping out debris. The main purpose of these plates is to protect the motor from external environmental factors such as heat, dust and moisture. Fiberglass reinforcements in FRP panels add strength and durability, making them resistant to corrosion, impact, and UV radiation. This ensures longevity and optimal functionality of the motor under harsh operating conditions.

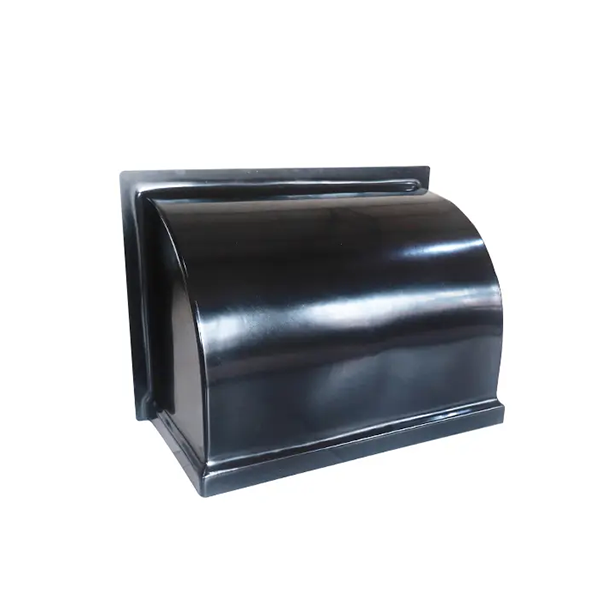

2. Fiberglass air intake cover:

The fiberglass air inlet hood, also known as the hood inlet, is a critical component of your motor’s ventilation system. These guards act as a protective barrier to prevent dust, dirt, and other contaminants from entering the motor components. Its smooth interior design allows for efficient airflow while minimizing resistance to incoming air. Additionally, the fiberglass construction of these shields adds structural integrity and durability, making them resistant to corrosion, chemical exposure, and extreme temperatures.

3. Integration of fiberglass motor cover and fiberglass air intake cover:

The combination of fiberglass motor cover and fiberglass air intake hood maximizes motor performance. By installing a comprehensive ventilation system, you can prevent the motor’s internal components from overheating, allowing for efficient operation and reducing the risk of premature motor failure. The FRP motor cover provides a solid layer of protection from external elements, and the fiberglass air intake hood ensures clean, uncontaminated air circulation within the motor assembly. This integration improves energy efficiency, reduces maintenance costs and extends the service life of the motor.

4. Advantages of fiberglass motor cover and fiberglass air intake cover:

- Enhanced motor performance: Use fiberglass motor covers and fiberglass air intake hoods to optimize motor function, thereby increasing efficiency and reducing energy consumption.

- Protection against environmental factors: These components protect the motor from temperature changes, dust, moisture and other external contaminants, ensuring its smooth operation and longevity.

- Noise reduction: FRP motor covers help reduce noise, making them ideal for industrial environments where noise pollution is a concern.

- Corrosion Resistance: Both components are made of fiberglass material, which provides excellent corrosion resistance, extending the life of the motor and reducing the need for maintenance.

In conclusion:

By utilizing fiberglass motor covers and fiberglass air intake hoods, industries can significantly improve the performance and efficiency of their motors. These components not only protect the motor from various environmental factors, but also improve ventilation and reduce noise levels. The combination of FRP motor cover and fiberglass air intake hood provides a powerful solution for optimizing motor performance, increasing energy efficiency and reducing maintenance costs. Adopting these advances in motor protection technology is a smart investment for an industry pursuing long-term success.

Post time: Nov-10-2023